BALLAST WATER TREATMENT

Optimarin was the first ever company to install a commercial ballast water treatment system in the year 2000.

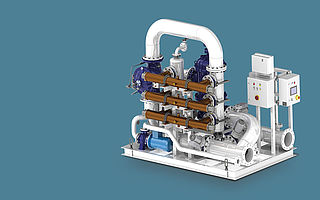

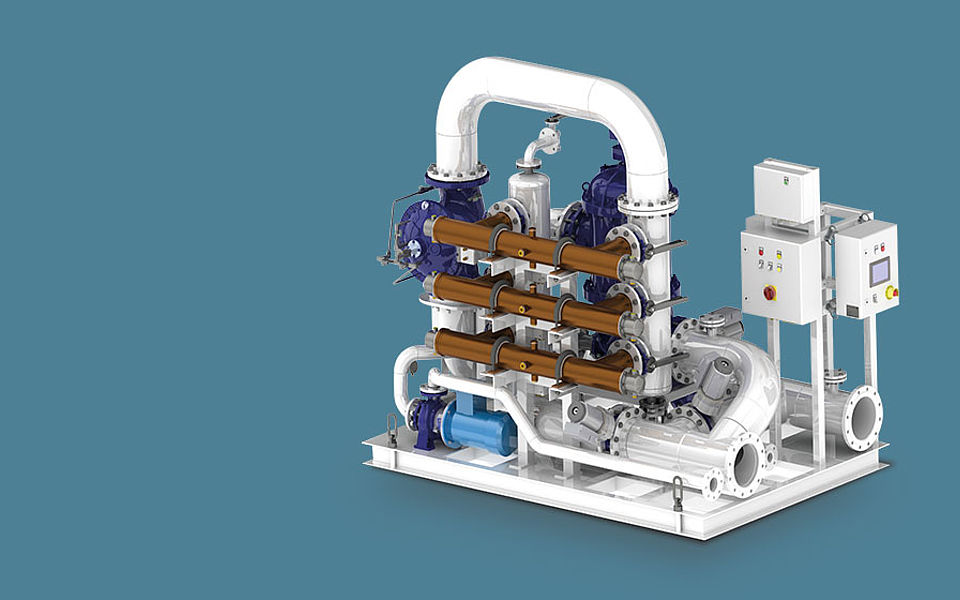

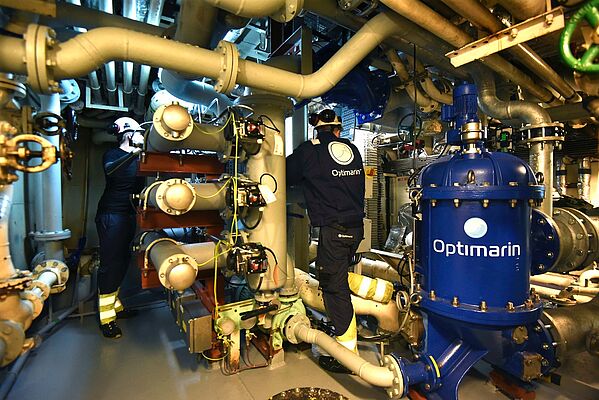

Optimarin Ballast Water Treatment System combines simplicity with innovation. During ballasting the ballast water flows through Optimarin’s proprietary filter. The filter removes larger organism and particles and back flushes them overboard at the ballasting location. After passing the filter, the ballast water continues through the UV chamber on its way to the ballast tanks. The UV light kills or inactivates organisms, viruses and bacteria in the ballast water. Optimarin uses the strongest UV lamps on the market used in ballast water treatment systems. This ensures best in class results also in extreme water conditions.

During de-ballasting the filter in automatically bypassed during de-ballasting, and the water receives a second UV-treatment during discharge as a safeguard to ensure compliance. With a modular nature, the system is flexible and easy to install on any vessel (newbuild and retrofit). Even those with the most restrictive space demands. The Optimarin system does not use nor generate chemicals in its process. Most importantly: It is simple to operate and maintain.

The Optimarin system has of course full IMO and USCG type approval.

STRONG PARTNERSHIP

ZEPPELIN POWER SYSTEMS

Zeppelin Power Systems is the official partner for the Optimarin ballast water treatment system in Germany, Poland, Russia and the CIS countries, excluding Ukraine. Zeppelin Power Systems offers their marine customers comprehensive system solutions for ballast water treatment. The portfolio covers the complete customized design, engineering and construction of the Optimarin Ballast System (OBS) such as worldwide after-sales service.

Furthermore, Zeppelin Power Systems is the official partner of Caterpillar for Cat and MaK engines and a leading provider of drive, propulsion, traction and energy systems.It is a legal entity of the Zeppelin group with almost 11,000 employees and a turnover of 3.7 bn euros and has been partnering with Caterpillar for more than 70 years. With over 1,000 employees, Zeppelin Power Systems offers their customers individual, highly efficient system solutions with comprehensive services for industrial and marine applications, the oil and gas industry, rail vehicles and power generation.

ENGINEERING - ALL FROM ONE SOURCE

The company has a vast engineering tradition The broad portfolio ranges from sales and consultancy, project planning, via design phase, customizing, commissioning and service. The in-house capabilities include experienced staff in sales and service, own CAD/design department, large engine outfitting plant including modern test rig facilities. We have a team of service technicians serving your application worldwide.

For more information see also:

OPTIMARIN

Optimarin AS was founded in 1994 in Stavanger, Norway and is one of the first companies in the world to develop a system for environmentally friendly purification of ballast water. Optimarin chose to create a simple and flexible solution that does not use nor generate chemicals in its process. The system is purely based on filtration as pre-treatment and high doses of UV irradiation for inactivation of marine organisms. The Optimarin Ballast System installed on board the Princess Cruises “Regal Princess” in year 2000 was the first ballast water treatment system on board an operating vessel. Through over 20 years of experience the Optimarin Ballast System has become one of the most sold systems for environmental treatment of ballast water.

Optimarin and Zeppelin Power Systems signed an agreement in September 2014, that Zeppelin will become the exclusive provider of planning, engineering and customization services for Optimarin’s Ballast System (OBS) in Germany, Poland and the CIS countries without Ukraine.

For more information see also:

www.optimarin.com

REFERENCES

Through 20 years of experience the Optimarin Ballast System has become one of the most sold systems for environmental treatment of ballast water.

Certificates

ISO 9001:2015

Quality Management

ISO 14001:2015

Environmental Management

ISO 45001:2018

Health and Safety Management

ISO 50001:2011

Energy Management