The missing link in ballast water management

A test sample of discharge ballast water is required by the local port to verify it meets environmental standards and non-compliance could mean costly downtime for a ship already on a tight schedule.

Such a scenario is being played out in real shipping operations around the world as voyage planning has been complicated by the need for reporting requirements to ports and class societies, testing and verification to meet strict IMO rules on ballast water management.

Every ship manager knows that time is money and balancing the ballast water equation represents another logistical headache as they seek to optimise the operational efficiency of large fleets spread across the world while minimising costs.

The IMO’s ballast water management (BWM) convention is intended to combat the release of harmful invasive aquatic species from ballast water discharges at ports worldwide.

This requires all ships to meet the so-called D2 standard, which specifies the maximum volume of viable organisms in ballast water discharges, by 2024.

Data deficiency

Installation or retrofit of ballast water treatment systems onboard vessels, aligned with a mandatory BWM plan, is seen as the most viable method for ship operators to achieve this standard.

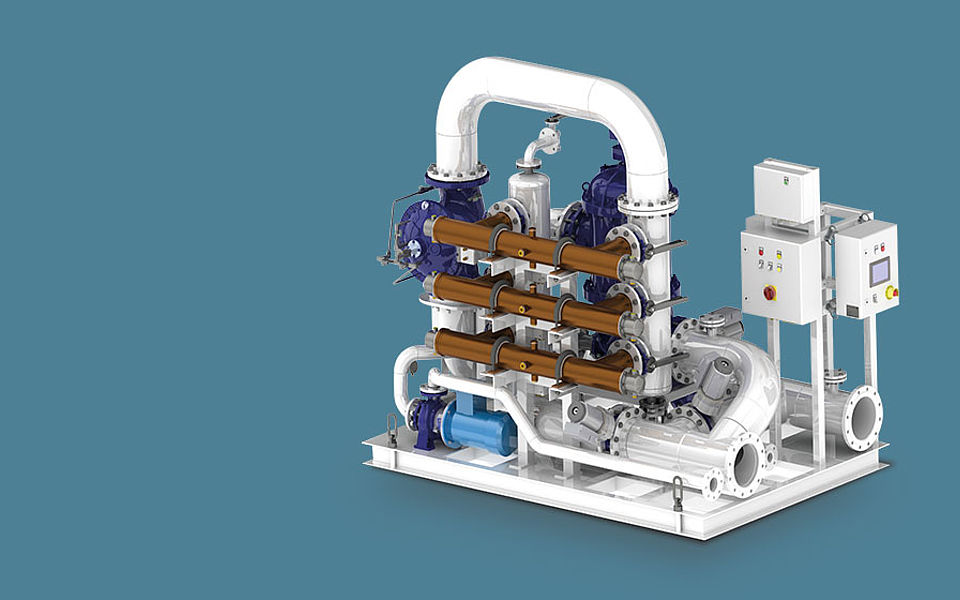

Systems such as those supplied by Norwegian ballast water treatment specialist Optimarin are effective in neutralising all potential invasive species through the use of ultraviolet irradiation and cleaning filters.

But its chief executive Leiv Kallestad says there still remain a number of fluid risk factors in ballast water operations due to the lack of global oversight over local water-quality standards that can affect regulatory compliance and commercial ship operation.

“There is also a need for more effective coordination and transfer of data between ship and shore to optimise ballast water treatment systems to achieve compliance,” he says.

Kallestad believes increased digitalisation could greatly improve the efficiency of such operations, eliminating much of the administrative workload to save time and money for ship operators, but the industry has been dragging its heels in this regard.

“This is the missing link that still needs to be addressed,” he says.