"We now finally have it set out in black and white that our UV systems also satisfy the strict requirements of the USCG," commented Tore Andersen, CEO of Optimarin. "We are delighted that our many years of investment in the development and testing of a reliable, effective, flexible and straightforward UV system have been rewarded with the recognition of the US environmental authority, and that we are now able to offer our customers technology that enjoys global recognition."

Reliable planning and investment for shipowners

"With the OBS from Optimarin, shipowners benefit from absolute reliability in planning and can rely on a proven, globally applicable and future-proof BWT system," adds Christoph Thomsen-Jung, Area Sales Manager responsible for ballast water treatment at Zeppelin Power Systems.

The application to the USCG was submitted in September 2016, and was subject to several land and sea-based tests performed by the independent Norwegian Institute for Water Research (NIVA), which is recognized by the USCG as partner to DNV GL. "At the end of 2015, the results of the first full-scale tests showed that the OBS' technically refined version that has been unchanged since 2009 fulfills the very strict US guidelines. "Recognition by the USCG now provides official confirmation of this result, meaning that our customers who are already using the OBS or have ordered one, can be sure that they have invested in the right system."

Field-tested with more than 300 BWT systems already installed

Optimarin is one of the largest providers of ballast water systems and has been on the market since 2000, and its UV system was recognized by the IMO in 2009. Since 2014, Zeppelin Power Systems has been official partner to the Norwegian BWT specialist and responsible for sales, distribution, engineering, installation, documentation and service in Germany, Poland, Russia and all GUS states, with the exception of Ukraine. Almost 500 Optimarin Ballast Water Systems (OBS) have now been sold worldwide. Of the over 300 systems already installed, more than 60 have been put in place as retrofit solutions. Shipowners that have opted for the OBS solution include, among others, Hapag-Lloyd, Saga Shipholding, MOL, Grieg Shipping Group, Gulf Offshore, Farstad Shipping, NYK, Nor Line and Evergreen Marine Corp.

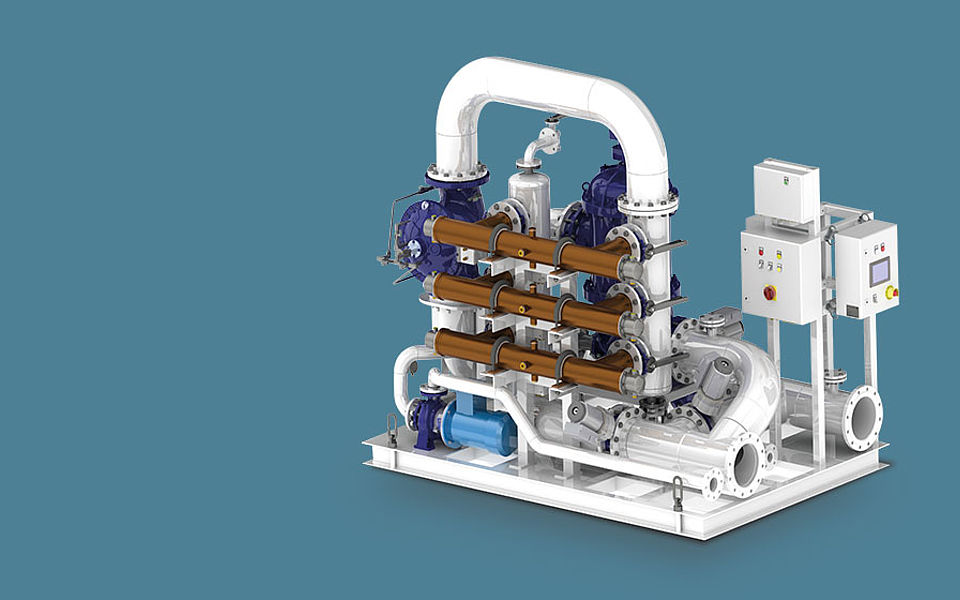

OBS – an absolutely unique system

The environmentally friendly OBS can be used for all water salinities, even enabling travel into sensitive ecosystems. With highly effective medium-pressure UV lights, the OBS is able to reliably kill invasive organisms in ballast water without the addition of chemicals or biocides. The system is designed for a volume flow of 50 to 3,000 m³/hour. Additional cleaning modules and manual cleaning are no longer needed. "In the OBS, we are therefore offering a unique and environmentally friendly system that is not only highly effective but also requires little service and maintenance, making it cost-efficient as well," commented Christoph Thomsen Jung. The OBS can be incorporated into the ship's control system, enabling easy operation from the control room or bridge.

Very well prepared for supply bottlenecks

The IMO ballast water convention will come into effect in a little under a year, on September 8, 2017. This is the last date for all new ships to have a recognized ballast water system on board, and the existing 40,000 plus ships worldwide need to be retrofitted within five years. "Time is short, both for shipowners and BWT manufacturers who need to manage bottlenecks in supply. Together with our partner Zeppelin Power Systems, we are very well equipped for this challenge," explained Optimarin CEO Tore Andersen.