No need for dry-docking, as Seatruck installs its own Optimarin BWT systems during normal service

Seatruck runs a fleet of 10 advanced ferries, ranging in capacity from 65‐150 trailers,

with over 60 weekly departures. This regular sailing schedule, between set ports,

ensured the firm could call on local contractors to ‘hop on and off’ and carry out

whatever engineering work the crew themselves couldn’t manage. It was, as

Seatruck Fleet Director Ben Coppack points out, a very efficient way to undertake

the installation.

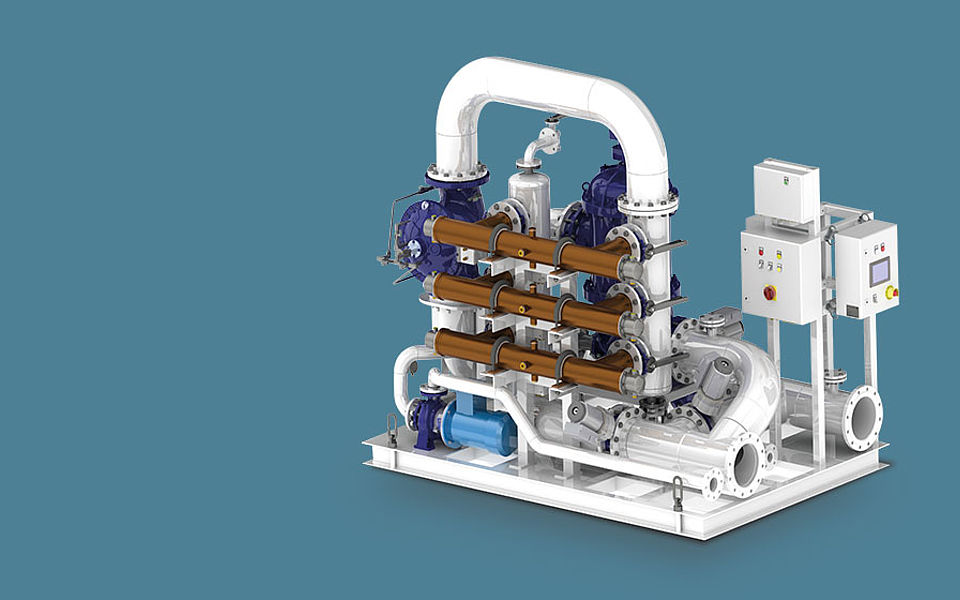

“We wanted Optimarin systems because of their track record of quality and

approvals, but also because, with their modular nature and operational simplicity,

they’re easy to install,” he notes. “As a short sea operator we had the goal of

carrying out all the work while the ships were in service, with no downtime, thus

keeping costs as low as possible.

“With the Optimarin systems and service – quickly responding to any queries or

issues we encountered – this wasn’t a problem. Our own crews actually performed

the vast majority of work themselves using Optimarin’s manuals. They were really

proud of the excellent work they did, and rightly so.“We’re very pleased we took this approach, ensuring port state compliance and BWT reliability ahead of regulatory demands.”

Seatruck began installation onboard the 5,300 dwt Seatruck Progress in November

last year. The remaining four systems were installed between January and the end of

September this year.

“This is the first time I’ve heard of a shipowner installing this number of systems

themselves while their vessels are in service,” comments Optimarin CEO Tore

Andersen. “It’s a testament both to their mission to provide optimal efficiency to

their stakeholders and customers, and to the simplicity of our environmentally

friendly, UV‐based System.

“With the ratification of the IMO Ballast Water Management convention, and the

strict regulations imposed by the US Coast Guard, the entire world fleet needs to

find proven, effective and reliable systems to ensure compliant sailing. This has the

potential to create huge bottlenecks at yards – and obviously increase installation

costs. However, Seatruck has shown that, with a system as straightforward and

effective as ours, there is another way. I think that’s something that will really

resonate with shipowners worldwide.”

Optimarin has now received orders for over 520 systems, with more than 330

installed worldwide, of which 150 are retrofits. The firm, which has focused

exclusively on BWT since its formation in 1994, was the first to receive full USCG

approval for its system, gaining certification in December last year.

“The market is picking up gradually,” Andersen concludes. “Shipowners need to

comply and they need systems that they can rely on. We’ve spent over 20 years

developing and refining our solution and can offer them unrivalled expertise and

service. With our sound financial base, strong group of investors, and experienced

global partners – including Goltens and Zeppelin – we can give owners not just the

technology they need, but the long‐term peace of mind and performance they

require.”

The Optimarin Ballast System (OBS) is fully approved by both IMO and USCG, with

certification through DNV GL, Lloyd’s, Bureau Veritas, MLIT Japan, and American

Bureau of Shipping. Optimarin customers include names of the order of The Royal

Netherlands Navy, Saga Shipholding, Technip, GulfMark, MOL, Solstad Farstad, and

Hapag Lloyd, amongst others.