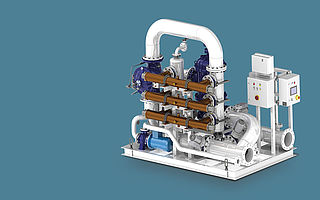

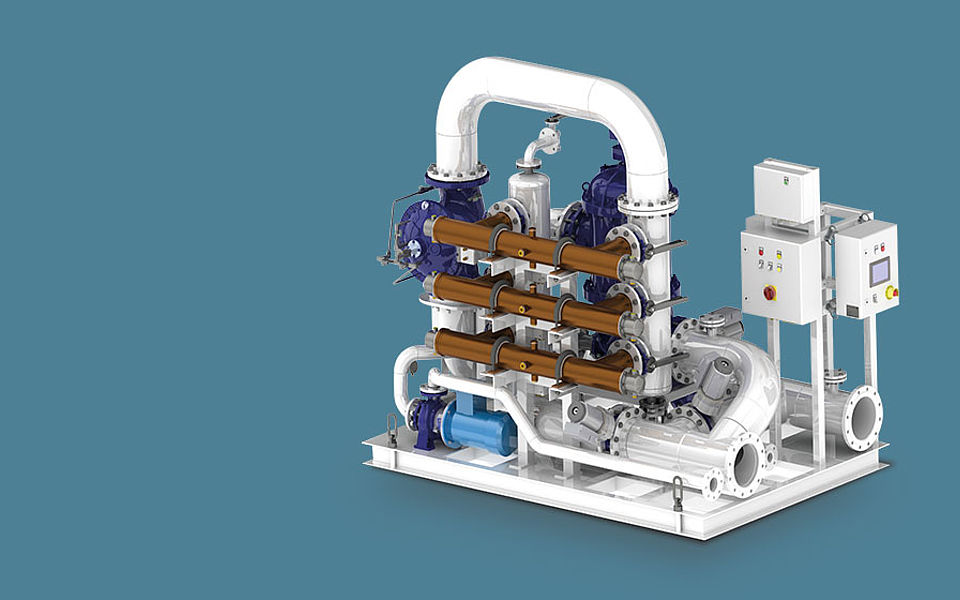

STRIPPING WITH EJECTOR

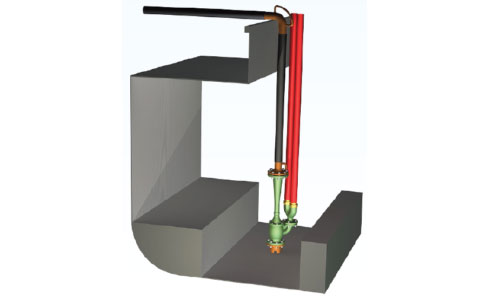

During tank emptying, the flow of ballast water to the suction pump can become restricted by the bottom structure; consequently, the main ballast pump will often lose suction before tank is completely empty. Adding the “Stripping” option to the Optimarin Ballast System, makes it easy for the operator to remove remaining ballast water through an ejector.

Stripping

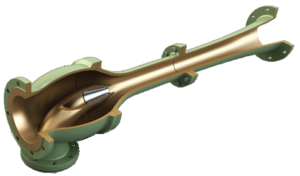

- Use existing ejector to suck out last remains of ballast water

- Ejector uses local sea water at high pressure to create suction, the ejectors discharge is a mixture of local harbor water and tank water.

- Drive water (local sea water) is filtered and the mixture of drive water and the ballast water is UV treated before discharge.

- DNV GL approved solution

Experience

- Optimarin has long and valuable experience with stripping operation

- Several piping configurations supported.

- Fully integrated in the Optimarin automation system

- A specially developed automatic air release system to vent out excessive air generated by the ejector.

- Automatic UV shutdown. Number of active UV lamps is automatically adjusted to the drive water capacity when starting a stripping operation.